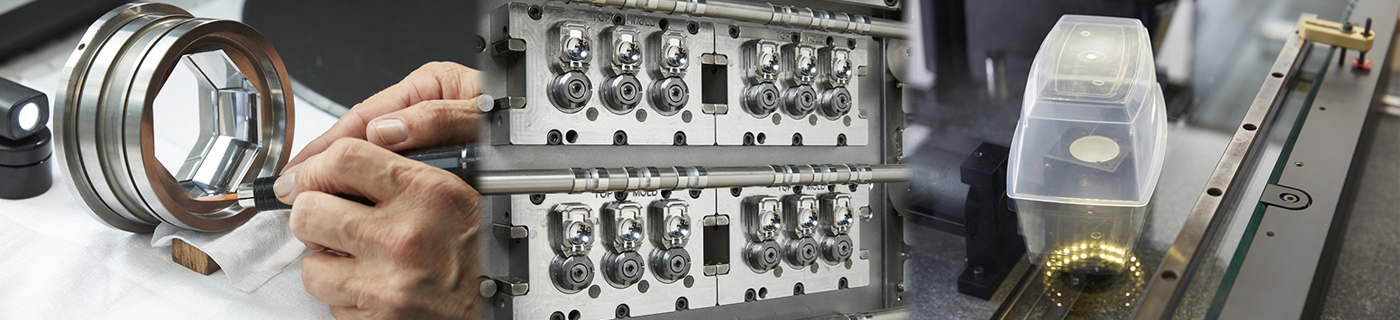

ERMO E-IMC: One-Cycle Mold Cap Closing for Flip-Top Caps

Since 2017, ERMO’s patented Electric In-Mold Closing (E-IMC) enables plastic injection molding lines to mold and close flip-top caps in a single cycle eliminating secondary independently deliveringking footprint and reducing total cost per part. Unlike conventional IMC systems, ERMO’s E-IMC uniquely generates a custom closing trajectory by commanding combined electric actuators simultaneously and independently delivering industrialised mold cap closing with programmable precision inside the tool.

Challenge: one-shot molding and closing for a dual-flap spice cap

A global brand needed a large spice-jar flip-top cap with two flaps to be molded and closed in one step within the plastic injection molding cycle-cutting production time and the finished-product cost. Traditionally this requires a mold plus a separate closing machine (extra assets, handling, and floor space).

Specs:

· Material: PP

· Cavities: 4

· Part weight: 7.95 g

· Functionality: two flaps needing a non-symmetrical, sequential closing trajectory (large flap first, then small)

Solution: ERMO’s Electronic In-Mold Closing (E-IMC)

ERMO implemented its standard E-IMC mechatronic module and controller to complete mold cap closing inside the mold immediately after filling/cooling before ejection. Only the motion curve was project-specific; the hardware stayed standard.

What makes ERMO’s solution unique: the E-IMC controller drives several combined axes, translation and rotation, at the same time and under independent commands, so the resulting trajectory is a true custom curve matched to the geometry and force profile of complex flip-top caps (like this dual-flap, non-symmetrical design). Typical IMC alternatives execute a fixed curve built from a translation then rotation sequence, which cannot close non-symmetrical double-door caps with the required precision and repeatability in one step. E-IMC is engineered specifically for these multi-stage, curved paths in plastic injection molding environments.

E-IMC Results and Benefits for Cap Molding

By executing the closing sequence inside the mold, E-IMC removes a downstream operation translating into tangible gains in throughput, cost, footprint, and quality:

-

One cycle, one line: mold and close flip-top caps in-tool no secondary closer, no inter-process handling, smaller footprint.

-

Lower total cost per part: fewer assets to buy/run/maintain; in-mold quality control via programmable motion cuts rework and scrap.

-

Operational flexibility: real-time curve edits keep dimensions and opening/closing forces within spec across material/color variability (incl. PCR/regrind).

-

Throughput reality: in-mold closing adds ~1 s vs. a non-closing step, yet removing the external station yields a better overall economics case.

-

Serviceability & uptime: remote diagnostics and curve updates speed ramps, SKU changes, and validations.

Why ERMO for mold cap closing in plastic injection molding

-

Adaptive curve : only ERMO’s E-IMC offers fully programmable, curved trajectories for complex flip-top caps adapting to different geometries, materials, and required force profiles.

-

High-volume DNA: 45+ years in high-precision injection molds (multi-cavity, multi-material, thin-wall) with ISO-9001 quality and a dedicated test center.

-

Sustainable electrics: electrical in-mold technologies (E-IMC, E-IMA, E-IML) to reduce energy and mechanical wear.

How ERMO’s Electronic In-Mold Closing (E-IMC) Works

· Programmable curved motion inside the tool: closes the larger flap first, then the smaller, following a non-linear path directly in-mold ideal for complex flip-top caps.

· On-press, real-time tuning: operators adjust the closing curve at the HMI to stabilise cap quality across resin or color lots (including recycled PP) no new mechanical parts needed.

· Remote support & re-use: ERMO can connect remotely to fine-tune curves; the same cabinet can be reused across molds by loading the proper curve/config file.

· Scalable architecture: demonstrated on 4 cavities, scalable to 24–36 while retaining the mold cap closing principle.

You want to know more about it ? Feel free to contact our team : ermobusinessteam@ermo-tech.com