AN ENTITY OF THE ERMO GROUP

ERPA is a French engineering company specialising in automation solutions to optimise your production lines or quality controls. Our company covers a wide range of activities such as pharmaceuticals, automotive, food processing, or small and medium industries.

Our know-how

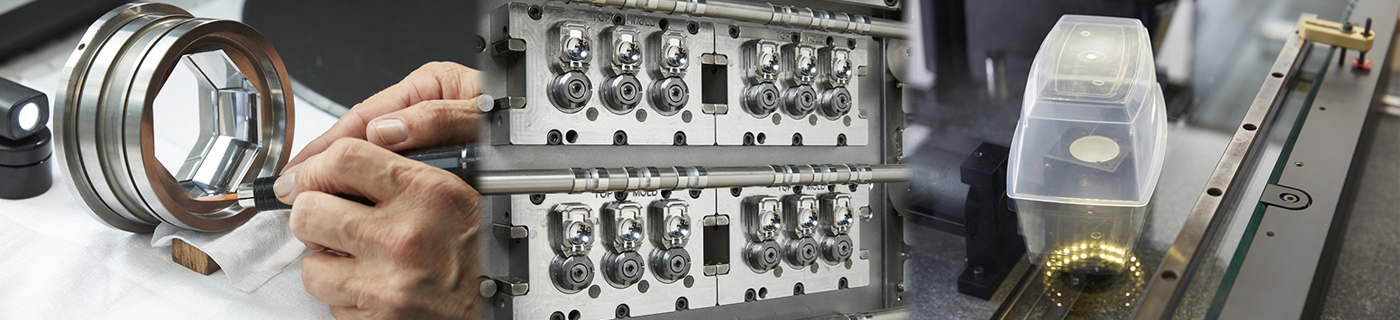

DESIGN OF SPECIAL MACHINES

AUTOMATION

ASSEMBLY AND FITTING

MECHANICAL AND ELECTRO-TECHNICAL DESIGN

PROGRAMMING

REFURBISHMENT AND RETROFIT

What makes us special

ERPA has recognised expertise in the conception and manufacturing of automation systems and assembly cells such as inspection machines, simple unloading robots, robotic units with protection and conveyors, crimping machines, vision machines, marking machines, etc.

Our team adapts to your requirements and technical constraints and accompanies you from the idea to the realization of your project.

ERPA is also committed to offering you ecological and economical solutions, in particular with its know-how in machine retrofitting, which is more and more in demand these days.

ERPA HIGHLIGHTS

- Sharp know-how in industrial processes, and even specifically in robotics in plastics processing

- Highly qualified design office

- Possibility of testing our customers' designs in the ERMO group for fine-tuning

- Post-design solutions: maintenance, assistance and training

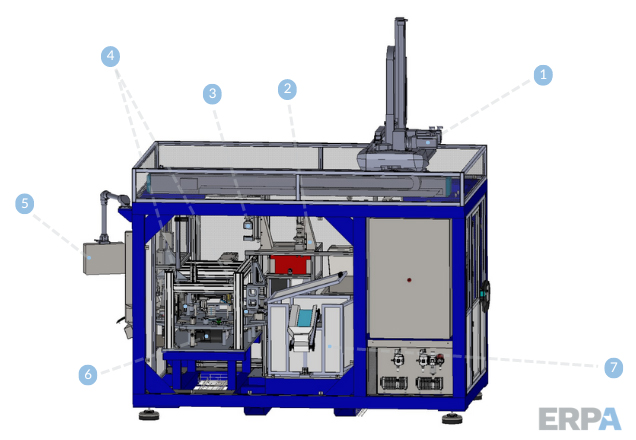

Design example

Robotic design in plastics processing

1. PRODUCT TRANSFER

Products are transferred from station to station via the SEPRO S5-25 robot without a handle

2. MARKING

By pneumatic micro-percussion with a marking head and Gravotech control unit for traceability

3. FINAL FLOW CONTROL OF THE ASSEMBLED PRODUCT

By 1 D670 double capillary flow meter from ATEQ France

4. QUALITY CONTROL OF THE ASSEMBLY OPERATIONS

Via the integration of 3 vision sensors IV2, KEYENCE

5. SET-UP AND PROGRAMMING

Via a Siemens 10 inch touch screen allowing a Human Machine Interface

6. WORKPIECE ORIENTATION

Integration of an MCPI type T50 cam indexing table with a multi-track rotary joint

7. FEEDING OF PLASTIC PRODUCTS

Integration of a VIBRA-TECH vibrating bowl and chute assembly

SEE THE VIDEO

OUR ENGAGEMENTS

Your project, our know-how. The key to success.

LISTENING AND COMMUNICATION

To be attentive to your expressed needs and to respond with clear and precise information

Take into account your demands and provide a satisfactory response within a reasonable leadtime

Dedicated project manager to follow up

Build a strong and long term relationship with you

QUALITY

Always offer you the best solutions, and the most ecological and economical ones

Be proactive about the legal compliances

Kick off meeting at the beginning and survey customer at the end

Respect delivery time

Ensure engineering feasibility at estimating stage

Continuously improve our services

SERVICE

To ensure continuity of our services included the after-sales

Search for automation solutions to optimize your process

Response time to your requests within maximum 48 hours

Engineering to retrofit your tools and equipment

OUR REFREENCES