Our know-how : from part design to mould and even more…

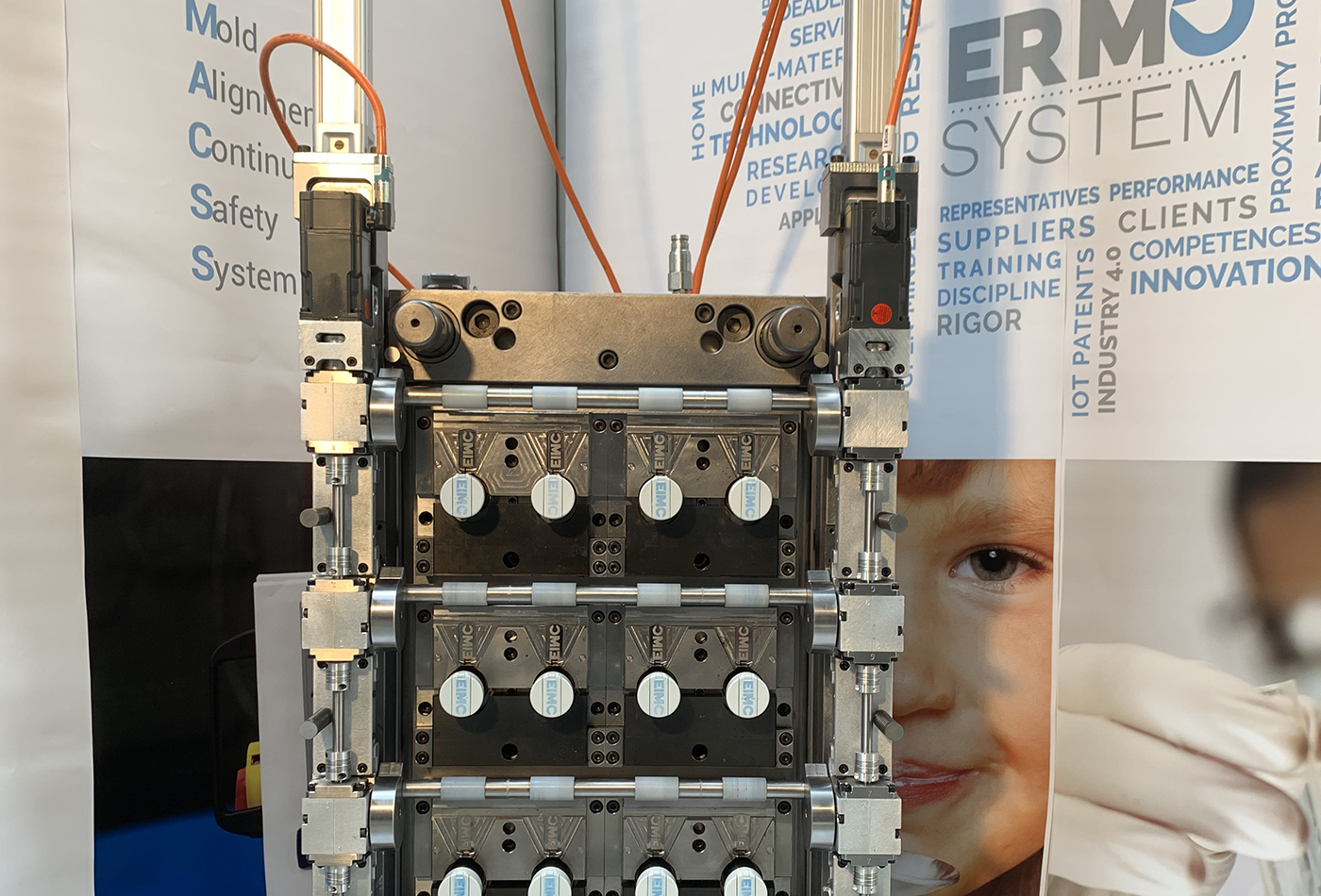

Mould, hot block, hot block control, assistance and automation solutions: 360° know-how

In addition to our mould design activity, we support our customers with a range of associated services (e.g. mould flow, assistance with production start-up, etc.) to provide them with a turnkey solution.

From the historical image of a simple mold supplier who designs and manufactures injection moulds, ERMO has strengthened its position by listening to the markets and its customers. We offer multiple services around the development of parts, the creation of prototypes, research and development, testing in our test centre with integrated quality department, and also maintenance and repair.

Our R&D department has been a key factor in ERMO's strong image and ability to innovate for many years by providing solutions such as the lightening of plastic parts (thin wall), multi-material parts, IMA etc. In addition, with our latest acquisition ERPA we offer new solutions in engineering with a manufacturing capacity of special machines and automated islands using collaborative robots among others.

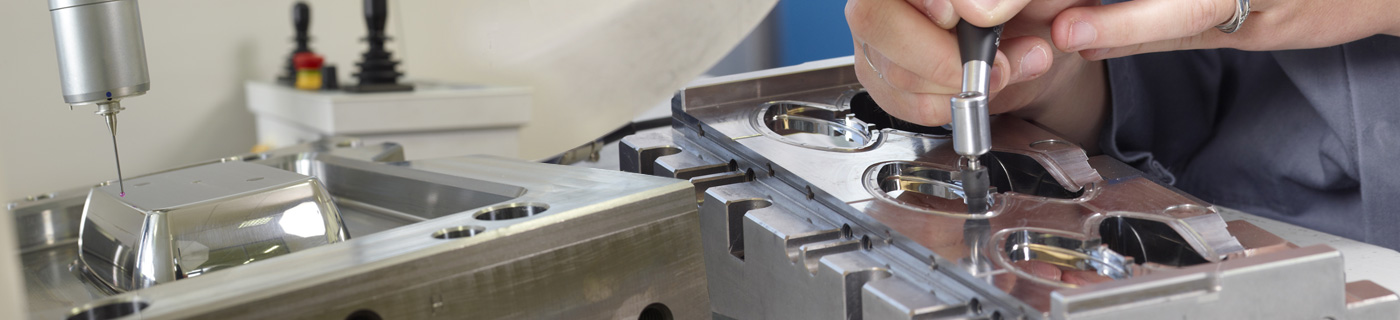

High precision, our second nature

Mastering a high-precision industry is not for everyone. By constantly adapting its research efforts, its tools, its processes, and also the skills of its employees, Ermo meets a demand for precision that has been growing steadily for four decades. Our impeccable steel finishing work offers the perfection of the part coming out of the mould.

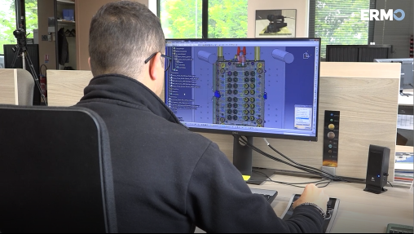

Innovation

Functionalities, materials, performance... To keep up with product evolution, the injection mould is able to combine different materials, colours and functions (closing, localised compression) in the same cycle. To adapt to production constraints and commercial objectives, its operation tends towards lower energy costs, the admission of new bio-sourced materials, the reduction of thicknesses and cycle times... Stimulated by the demands of its customers, Ermo has gone beyond the traditional framework of subcontracting to reach the rank of innovative company, approved by the Ministry of Research.

Intelligent technology

Firmly committed to the future, the Ermo Group is gradually integrating the new industrial reality of 4.0. This major evolution, which has already changed the face of production (robotisation, digitalisation), is in the process of revolutionising the mould itself, making it communicative and tending towards operational excellence (programming, production, maintenance monitoring).