Caps circular economy : interview with Marco Lucchiari Tucci

With the new European regulations on packaging and waste, plastic must become more circular: less waste, more recycling, and more post-consumer materials. In the production of valve caps, the electric closure integrated into the mold replaces the pneumatic closure and improves precision and repeatability, particularly with recycled materials.

The new European regulation on packaging and packaging waste (RPDE, Regulation 2025/40) is forcing the entire plastic packaging industry to reorient itself. Brussels' stated objective is to minimize the amount of packaging and waste produced, limit the use of virgin raw materials, and steer the system towards a more circular model, in which all packaging is designed to be efficiently recycled and, where possible, reused.

In this context, even a tiny component such as a plastic cap becomes a platform for technological innovation and a point of contact between the ecological transition and the digital transformation of molding processes.

PPWR and plastic packaging: three operational guidelines for 2030-2040

With regard to plastic packaging, the regulation introduces three main guidelines: all packaging must be designed to be recycled by 2030 according to harmonized criteria; it must meet minimum requirements for post-consumer recycled plastic content, with thresholds differentiated according to product type; it must contribute to the overall packaging waste reduction target, set at a reduction of up to 15% by 2040 compared to 2018 levels.

From a regulatory standpoint, another important aspect must be considered: plastic components representing less than 5% of the total weight of the packaging do not fully meet the minimum recycled content requirements. In practice, the cap could even be excluded from the strictest percentages.

Plastic caps and brand requirements: more recycled content, less weight, same recyclability

In reality, major brands are always demanding a higher proportion of recycled materials in these components in order to reduce their weight while preserving their overall recyclability. For those who produce millions of caps per day, often for beverage, cosmetics, or detergent brands, the real challenge lies in the reproducibility of the process: any variation in material or color can lead to broken hinges, poor cap sealing, increased waste, and machine downtime.

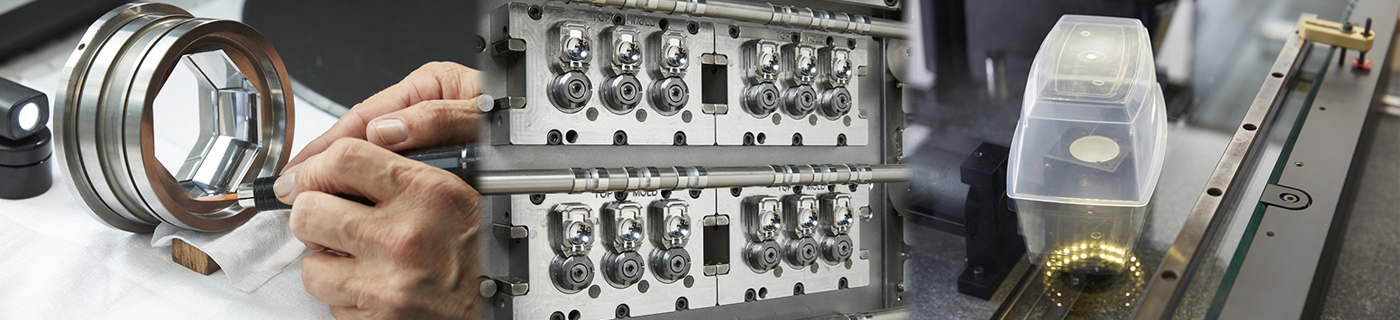

This is where the mold-integrated electric closure comes in, a technology that innovates in an operation already known as automatic cap closure, but shifts the center of gravity from the pneumatic world to the mechatronic world.

From pneumatic to electric: how electric mold closure works

In the production of valve caps, the molding closure process has been used for a long time: the part is molded open and closed automatically before ejection. In traditional systems, the movement is controlled by pneumatic cylinders with a fixed stroke, which is identical for all parts.

The electric closure integrated into the mold retains the same principle but replaces air with programmable electric axes: two motors drive the cap's translation and rotation along a software-defined trajectory, with the possibility of inserting stops, a second final “click,” and speed variations at critical points.

Production benefits: faster cycles, less waste, and less compressed air

In production, this translates into faster molding cycles (5 to 8% time savings), less waste (up to 50% less), and more precise closure, with fewer defective parts at the hinges. The mold is delivered with the cap already closed, without the need for an external closing machine, which reduces space requirements, handling, maintenance, and compressed air consumption.

From an automation standpoint, the equipment is modular: the same control cabinet and side motors can be used for different molds, with only the movement curve stored as a recipe changing.

Mold-integrated electric closure and PCR: digital solutions to stay compliant with specifications

This flexibility is particularly important in light of the minimum recycled plastic content requirements introduced by the PPWR. Post-consumer materials do not always behave like virgin materials: viscosity, shrinkage, cooling times, and hinge strength can vary from batch to batch, especially in the presence of complex blends or high percentages of PCR (post-consumer recycled plastic).

With a rigid pneumatic closure, the movement remains the same regardless of material variations, which increases the risk of producing caps that are at the limit of specifications or outside specifications, and therefore waste. In contrast, a programmable electric closure allows specific recipes to be defined for each combination of color and material, including those containing a high percentage of recycled materials.

This technology facilitates the use of PCR: it does not solve the intrinsic problems of recycled materials on its own, but it makes the process robust enough to accept a wider variety of raw materials without compromising quality or productivity. This is an important step forward in making the PPWR's minimum recycled content requirements applicable on an industrial scale, in a context where brands are demanding ever-higher percentages of post-consumer materials, even for the smallest packaging components.

Competitiveness, ESG criteria, and supply chain value: return on investment, data, and microprocess innovations

Analysis of application cases shows that by combining faster cycles, reduced waste, elimination of an external closing machine, and lower compressed air consumption, the return on investment for medium-sized multi-cavity molds can be less than one year. The advantage is therefore mainly industrial: an increase in the number of compliant parts per hour, reduced energy consumption per mold, reduced downtime for mechanical adjustments, and better availability of process data, which can be used for ESG (environmental, social, and governance) purposes, when large customers require accurate information on consumption, waste, and environmental performance.

The most concrete benefits are further up the supply chain, in the relationship between the cap printer and the brand owner. For the end consumer, it is difficult to see a direct link between molded cap technology and the shampoo bottle they buy: the price does not drop significantly and the cap looks the same as it did yesterday.

However, there are indirect but real benefits: more uniform quality standards, increased reliability of cap hinges, a greater likelihood of using recycled plastic in these components, and reduced production waste and energy consumption throughout the supply chain. These benefits are significant when considering the hundreds of millions of parts produced each year, not just on the scale of an individual purchase.

The case of plastic caps perfectly illustrates how the response to PPWR regulations requires not only major revolutions in materials, but also micro-innovations in processes, often invisible to the end user. Electric actuators instead of pneumatic cylinders, programmed motion curves instead of fixed kinematics, digital recipes linked to the type of material, remote assistance for parameterization: these are all pieces of a larger puzzle that combines the requirements of the new European regulation, the transition to Industry 4.0, and the need to preserve industrial margins in a sector where the price of each part is measured in cents.

All rights reserved - Article from the italian media Agenda Digitale