Beauty & Home

Food & Beverage

Thin wall

Ermo group’s commercial activities are built on a solid foundation of three demanding contractors: the medical, cosmetics and food industries.

Over the last thirty years, we have been able to adapt to their respective requirements and maintain their trust: aesthetic changes, work on the thicknesses and cycle times to fulfil their goals in reducing production costs.

Constant innovation means we can now consider new outlets in industrial sectors where processes could benefit from Ermo technology: controlling intake parameters to produce controlled thicknesses, injection and assembly within the mould itself, colour and material combinations.

Ermo group’s commercial activities are built on a solid foundation of three demanding contractors: the medical, cosmetics and food industries.

Over the last thirty years, we have been able to adapt to their respective requirements and maintain their trust: aesthetic changes, work on the thicknesses and cycle times to fulfil their goals in reducing production costs.

Constant innovation means we can now consider new outlets in industrial sectors where processes could benefit from Ermo technology: controlling intake parameters to produce controlled thicknesses, injection and assembly within the mould itself, colour and material combinations..

Ermo group’s commercial activities are built on a solid foundation of three demanding contractors: the medical, cosmetics and food industries.

Over the last thirty years, we have been able to adapt to their respective requirements and maintain their trust: aesthetic changes, work on the thicknesses and cycle times to fulfil their goals in reducing production costs.

Constant innovation means we can now consider new outlets in industrial sectors where processes could benefit from Ermo technology: controlling intake parameters to produce controlled thicknesses, injection and assembly within the mould itself, colour and material combinations.

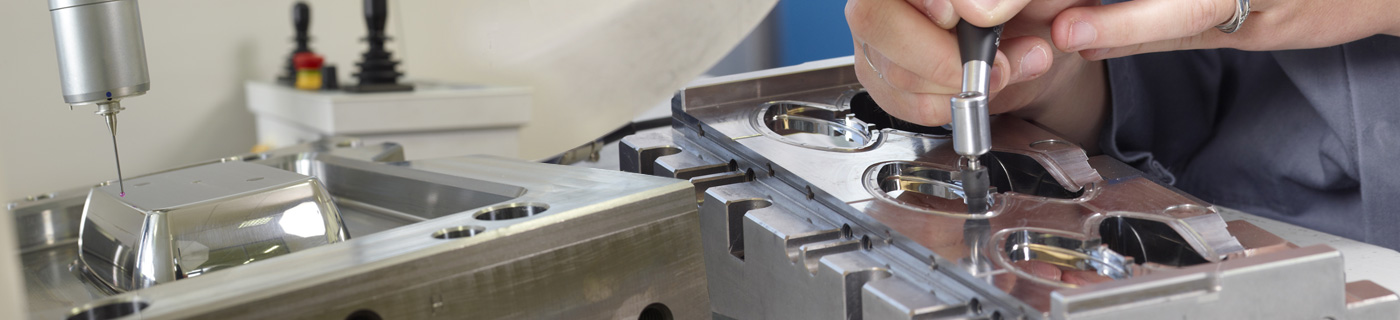

ERMO has recently expanded its business into the manufacture of ceramic and metallic injection moulds.

ERMO also manufactures high precision moulds for the automotive, electronics and connector industries among others.