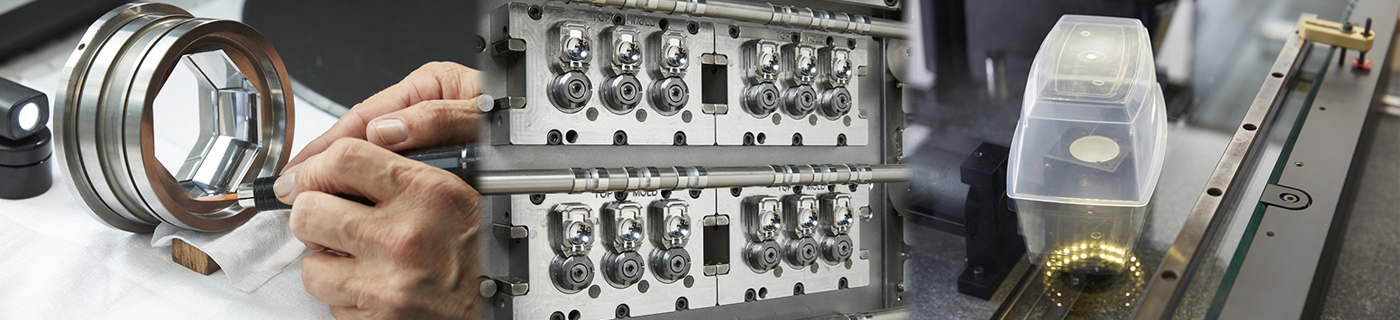

Semi-autonomous production: A project by ERMO & ERPA

For nearly three decades, ERPA has been a leader in the field of automation and robotics, offering innovative, tailor-made solutions to meet its customers' needs. Thanks to its technical expertise and know-how in production line robotisation, ERPA has been able to evolve and adapt to the challenges of a constantly changing market.

ERPA and ERMO: a synergy serving industrial innovation

Having been part of the ERMO group for four years now, ERPA is strengthening its capabilities by offering global solutions combining moulds and automation systems. This strategic collaboration enables our customers to benefit from an integrated approach, combining ERMO's mould expertise with ERPA's state-of-the-art automation technologies. Together, we provide our customers with optimised solutions that promote greater profitability, reduced waste and significantly improved productivity.

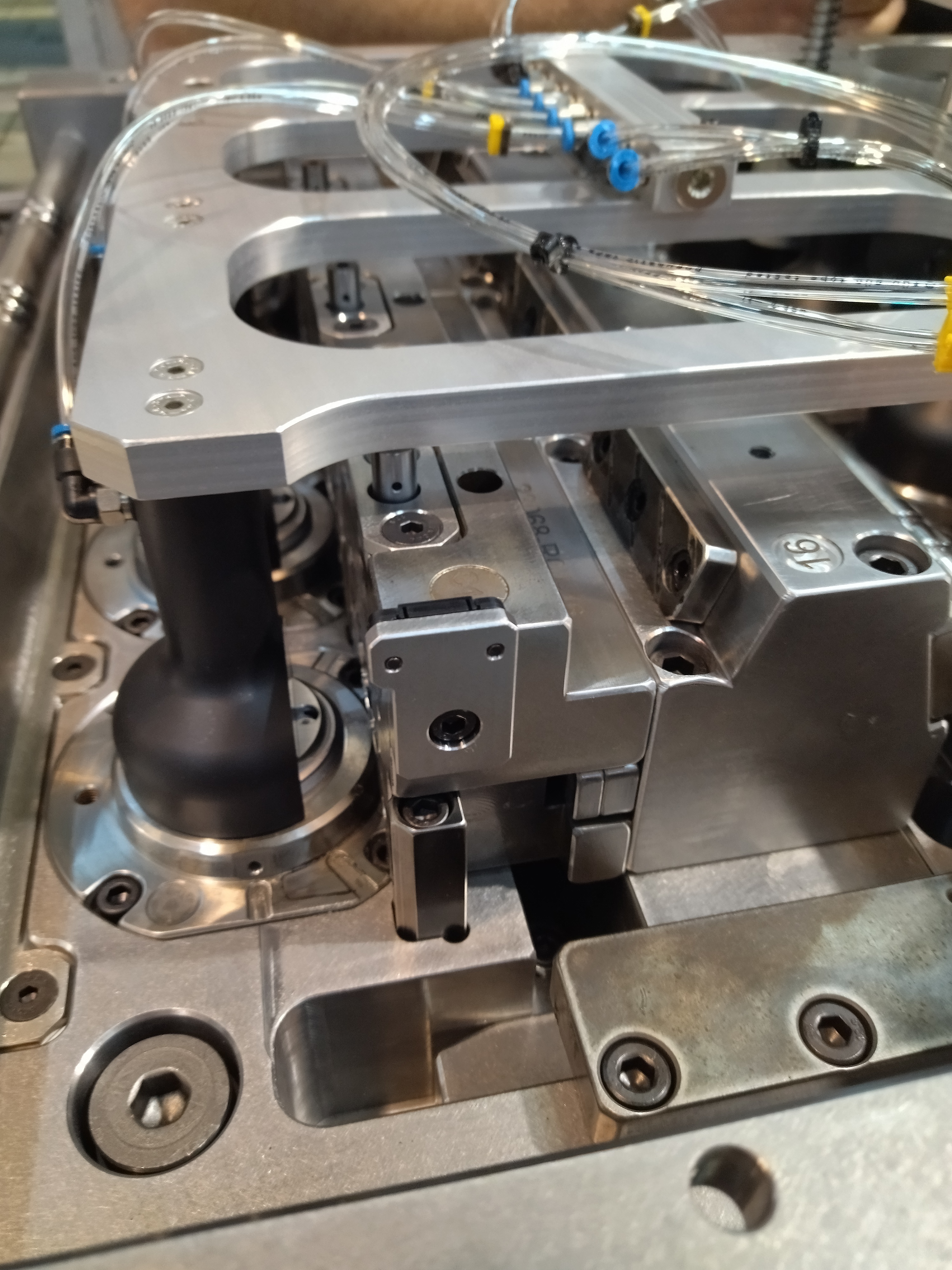

Example of expertise: A 16-cavity gripping hand coupled to an ERMO mould

One concrete example of this collaboration between ERMO and ERPA is our 16-cavity gripper hand, specially designed to work in tandem with an ERMO mould. This advanced technology perfectly embodies our ambition to provide high-performance, reliable semi-autonomous production solutions.

Key objectives of this innovation :

- Optimum quality: The gripper hand is designed to completely eliminate production waste, guaranteeing compliant products at every stage of the process.

- Increased productivity: Based on a fully automated production cycle, this solution increases output and reduces cycle times. Repetitive tasks are carried out with unrivalled precision, freeing up operators for higher value-added tasks.

More photos in our LinkedIn publication.

Why opt for semi-autonomous production?

The semi-autonomous production solutions developed by ERPA and ERMO meet the growing needs of companies wishing to optimise their production chain without compromising quality. Thanks to automation, production times are reduced, raw material losses minimised and operating costs optimised.

By investing in semi-autonomous technologies, our customers benefit from a rapid return on investment while meeting the demands of the modern market: flexibility, precision and increased productivity.

Conclusion: Innovation for tomorrow's industry

With nearly 30 years' experience and proven expertise in automation, ERPA, in partnership with ERMO, continues to innovate to offer its customers high-quality semi-autonomous production solutions. The 16-cavity gripper hand combined with an ERMO mould is a perfect example of this, illustrating our commitment to high-quality, high-performance production.

To find out how ERMO & ERPA solutions can transform your production, contact us today. Together, we can optimise your production lines and prepare for the industry of tomorrow.