The polisher’s job

Christian Horeau, manager of the ERMO group's polishing laboratory, explains his job in more detail.

To be a polisher, there are 4 essential qualities to acquire. You must be patient, rigorous, methodical and meticulous.

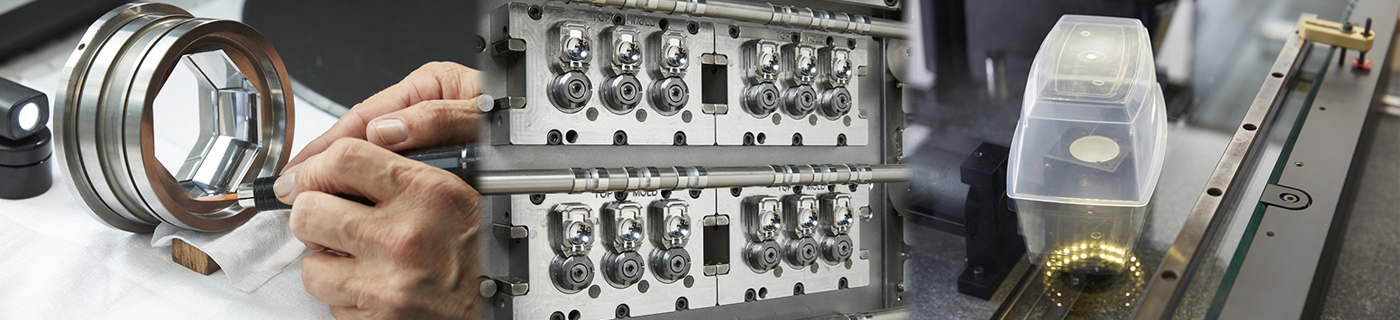

The purpose of polishing is to render the steel part or electrodes in a representative aspect of the customer's request. For this manual work, the polisher achieves impeccable surface conditions, which can go as far as a shiny, streak-free surface, depending on the Ra request (e.g.: mirror polishing). The polishers identify all the interventions that they will have to carry out to have the best final. They use different tools such as grinding wheels, polishing stones, ceramic sticks (ultrasound)...

To control all these surfaces, the polishers work under LED magnifiers or cameras (magnify 45 times).

As this process is meticulous, the complexity of some parts can require more than 15 hours of work.

ERMO trains its staff internally because there is no longer any polishing training. ERMO has implemented a progressive internal training program that has enabled it to build a team of 6 employees, including 3 women.